Scene 1 (0s)

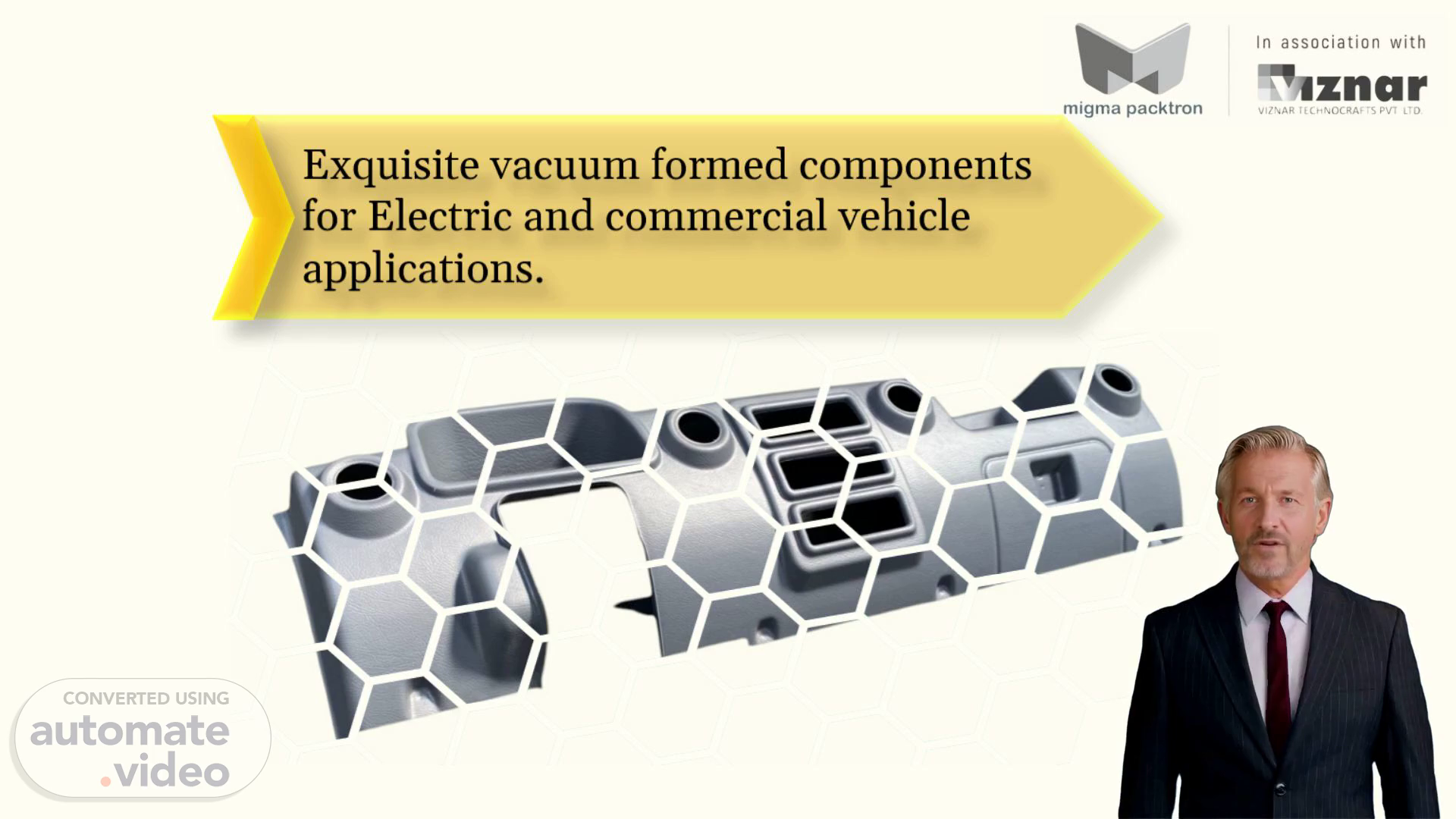

[Virtual Presenter] Hello everyone, it is great to be here today. Today we will talk about Migma Packtron, a vacuum forming company that has been providing cutting-edge solutions for the automotive industry since its establishment in 1988. Our focus is on manufacturing vacuum formed engineering products and automotive components, and we are committed to revolutionizing the automotive industry through exceptional vacuum forming solutions, while delivering unparalleled quality, innovations, and sustainable products to our valued partners. We have over 150 skilled employees, led by experienced professionals with expertise in manufacturing and sales, and we have top-notch assembly and fabrication facilities, as well as a thermoforming R&D center and in-house tool room, equipped with machines having P-L-C and sandwich control heaters. We are constantly innovating and improving our processes to provide the best possible solutions to our customers. Today, we will be discussing vacuum forming and how it can be used to create exquisite vacuum formed components for electric and commercial vehicle applications..

Scene 2 (1m 13s)

[Audio] Our focus is on manufacturing vacuum formed engineering products and automotive components. This has made us a leading provider of cutting-edge solutions for the automotive industry. Our state-of-the-art vacuum forming technology enables us to deliver high-quality components efficiently and economically, making us a valuable partner for automotive manufacturers. We take pride in the work we do and the impact we have in the automotive industry. We quickly create prototypes for our customers using the latest technology, saving them time and money in the long run. We understand that speed and accuracy are key in the prototyping process, and we take pride in our ability to deliver high-quality prototypes quickly and efficiently. We have the expertise and technology to help bring your vision to life, whether you're looking to create a new component for an electric vehicle or a commercial vehicle. Thank you for joining us on this journey through Migma Packtron. We hope you found this information helpful, and we look forward to working with you in the future..

Scene 3 (2m 14s)

[Audio] Our organization believes that creativity is a vital component of our success. We are constantly exploring new ways to create exceptional vacuum formed components for electric and commercial vehicle applications. Our vacuum forming solutions are unparalleled and have revolutionized the automotive industry. We prioritize innovation and sustainability in all of our operations. Our commitment to excellence and our dedication to meeting the needs of our valued partners have earned us a reputation as a leader in our field..

Scene 4 (2m 48s)

[Audio] Our team has over 35 years of experience in vacuum forming technology for electric and commercial vehicle applications. Our expertise enables us to design and produce exquisite vacuum formed components that are both functional and visually appealing. Our Operations Director, Aditya Patankar, has sales expertise and can understand customer requirements, design optimal solutions, customize the product/ service, and close the deal. We believe that our vacuum forming technology can help you create the future of transportation with innovative and high-quality components..

Scene 5 (3m 26s)

[Audio] Our team is a leader in the thermoforming industry, with a vast manufacturing area of 35000 square feet in Indore and around 20000 square feet in Pune (Chakan). We have a dedicated team of over 150 skilled employees, including vacuum forming machines capable of up to 800 millimeters draw, 5 C-N-C trimming machines, 3D printers, and a robotic arm for precision trimming and tooling. Our top-notch assembly and fabrication facilities ensure the production of exquisite vacuum formed components for electric and commercial vehicle applications. We use cutting-edge technology and equipment to deliver high-quality products to our customers..

Scene 6 (4m 15s)

[Audio] Our team of expert engineers is dedicated to creating components with unparalleled precision and quality. We understand that time is of the essence in today's fast-paced industry, which is why we offer rapid prototyping solutions. Our in-house tool shop uses the latest C-N-C and 3D printing technologies to fabricate high-quality molds and dies, ensuring tight tolerances and repeatable part quality. This offers our clients a complete solution under one roof. With our advance forming solutions, we are able to deliver exquisite vacuum-formed components for electric and commercial vehicle applications..

Scene 7 (4m 54s)

[Audio] 1. Our dashboards are manufactured with intricate assemblies. 2. We produce high-volume, cost-effective parts with precision. 3. C-N-C routers and robotics enable us to manufacture components of unparalleled complexity. 4. Our skilled assemblers produce unique solutions for our customers. 5. We emphasize quality assurance in everything we do..

Scene 8 (5m 21s)

[Audio] Our presentation includes high-quality automotive dashboard components and interior trim. Our vacuum forming process is innovative and allows us to create aerodynamic exterior body panels that meet the design and engineering requirements of the automotive industry. Our vacuum formed components are designed to be functional and visually stunning, and we are always pushing the limits of what is possible with this technology..

Scene 9 (5m 47s)

[Audio] We are discussing vacuum forming dashboard design. Our expertise in vacuum formed components allows us to provide high-quality products that exceed our customers' expectations. We are dedicated to delivering exquisite components that capture the luxurious look and tactile experience of a high-end car dashboard..

Scene 10 (6m 10s)

[Audio] 1. Designing, prototyping, and vacuum forming. 2. Mudguards and fenders. 3. Electric and commercial vehicles. 4. tata and Volvo Eicher. 5. Enhance the exterior underbody components..

Scene 11 (6m 30s)

[Audio] We specialize in forming electric and commercial vehicle components, specifically focusing on the front inner. Our advanced techniques and expert assembly expertise ensure success in deep draw and bulky component forming. Our vacuum formed components are exquisite and designed for a range of electric and commercial vehicle applications. We deliver high-quality, reliable components that meet our customers' demands..

Scene 12 (6m 58s)

4. Rear inner. Deep draw and bulky components pose complex challenges in forming, but we've achieved success through advanced techniques and expert assembly expertise..

Scene 13 (7m 6s)

[Audio] 1. We are now on slide 13 of our presentation on Forming the Future Designing, Prototyping, and Vacuum forming. Today, we will be focusing on interior trims for electric and commercial vehicle applications. Our vacuum forming expertise enables us to create automotive dashboard components that deliver a premium, integrated look and feel. With our innovative techniques and state-of-the-art technology, we can help you bring your vision to life and create components that stand out in any vehicle. 2. We will be focusing on interior trims for electric and commercial vehicle applications on slide 13 of our presentation on Forming the Future Designing, Prototyping, and Vacuum forming. Our vacuum forming expertise enables us to create automotive dashboard components that deliver a premium, integrated look and feel. With our innovative techniques and state-of-the-art technology, we can help you bring your vision to life and create components that stand out in any vehicle..

Scene 14 (8m 15s)

[Audio] Our vacuum forming capabilities for automotive dashboard components provide a premium, integrated look and feel. We produce components that deliver superior quality and design. Our vacuum formed door panels are ideal for electric and commercial vehicle applications..

Scene 15 (8m 34s)

7. Roof Panel (external). Our vacuum forming expertise allows us to produce automotive dashboard components that deliver a premium, integrated look and feel..

Scene 16 (8m 42s)

[Audio] Our company has multiple plant locations in India, including Pune and Indore, as well as a warehouse in Dharwad and Lucknow. This setup allows us to reduce transport costs and ensure faster delivery times for our customers. Our design, tooling and fixture development under one roof has greatly improved our turnaround time. Our own manufactured vacuum forming machine minimizes downtime in case of any breakdowns. We are well-equipped and future ready with state-of-the-art robots, 5-axis router for trimming and 3D printing facility. Our strengths include providing exquisite vacuum formed components for electric and commercial vehicle applications..

Scene 17 (9m 23s)

[Audio] We create exquisite vacuum formed components that are both functional and visually appealing. We prioritize recycling and proper waste disposal, reducing our environmental impact by minimizing landfill waste from our manufacturing processes. This allows us to create a sustainable future for our planet. Additionally, our vacuum formed components are lighter in weight, leading to increased fuel efficiency and reduced emissions. We utilize energy-efficient equipment and practices to lower greenhouse gas emissions and reduce our carbon footprint, providing our customers with a more sustainable and eco-friendly option. Overall, vacuum forming components are an excellent choice for electric and commercial vehicle applications, offering a unique combination of functionality, aesthetics, and sustainability, making them a valuable addition to any vehicle design..

Scene 18 (10m 19s)

[Audio] We showcase our innovative vacuum formed solutions in our presentation on Forming the Future. Our vacuum formed components have been designed specifically for electric and commercial vehicle applications, and have enabled leading automotive manufacturers to enhance their product designs and quality. Hear from our satisfied customers about the transformative impact of our cutting-edge technologies and dedicated service. From optimizing production efficiency to delivering superior component performance, our custom vacuum formed parts have become a trusted choice for top automotive brands worldwide. At , we are dedicated to providing our clients with the highest quality vacuum formed components. Our team of experts has years of experience in designing, prototyping, and vacuum forming, and we are constantly innovating to improve our processes and technologies..

Scene 19 (11m 14s)

[Audio] We have received the Best On time Delivery Award by Olectra BYD 2023 for our commitment to delivering high-quality vacuum formed components on time. Additionally, we have been recognized for our outstanding supply chain management by Eicher in 2015. Our dedication to providing excellent customer service and efficient operations has earned us this prestigious award. We are also featured in Motor India magazine and the MP Hindi News Paper. We are committed to continuing to innovate and lead in the vacuum forming industry, and we look forward to forming the future of electric and commercial vehicle applications..

Scene 20 (11m 55s)

[Audio] Our manufacturing processes are implemented with the ISO 14001:2015 and ISO 9001:2016 quality management systems, ensuring that our components meet the highest standards of quality and performance. Our components are designed to be durable and long-lasting, and are made from only the finest materials. We offer a wide range of components that are perfect for electric and commercial vehicle applications, including dashboard displays, steering wheels, and other interior components. Our commitment to quality and customer satisfaction is backed by our vacuum formed components, which are designed to provide optimal performance and durability. Look no further than migma packtron for a reliable and high-quality vacuum formed component for your electric or commercial vehicle..

Scene 21 (12m 52s)

[Audio] Utilizing Industry Knowledge to Innovate into New Automotive Product Categories and Applications Worldwide Exploring Sustainability Solutions Enhancing Eco-Friendly Vacuum Forming Processes and Materials to Cater to the Increasing Demand Venturing into Unrelated Industries to Explore the Potential Applications of our Vacuum Forming Technology..

Scene 22 (13m 15s)

[Audio] We design, prototype, and vacuum form products for electric and commercial vehicle applications. Our vacuum formed components are engineered to meet the demands of the industry and exceed expectations. We're committed to innovation and pushing the boundaries of what's possible. We constantly explore new opportunities and technologies to stay at the forefront of the industry. Our team of experts is dedicated to delivering high-quality, reliable products that exceed our customers' expectations. We're proud to be associated with companies like Ashok Leyland, Volvo, Isuzu, Tata Motors, E-K-A Mobility, Kinetic, Green J-B-M Auto, and J-B-M Auto. These companies share our commitment to innovation and excellence, and we're honored to be associated with them. We believe in designing products that are both functional and aesthetically pleasing. Our vacuum formed components are engineered to meet the highest standards of design and quality. We're committed to delivering products that are not only functional but also visually appealing. We're part of the Tata Autocomp Systems, and we're excited to be a part of the industry's leading automotive solutions provider. Our capabilities in designing, prototyping, and vacuum forming are just the beginning of what we can achieve. We're constantly exploring new opportunities and technologies to stay at the forefront of the industry. We're dedicated to delivering innovative solutions that exceed our customers' expectations. We're committed to excellence, and we're constantly exploring new opportunities and technologies to stay at the forefront of the industry. We're excited to be part of the future of the automotive industry..

Scene 23 (14m 59s)

[Audio] Our corporate office is located at Factory 12/2, Progressive Industrial Park, Tigaria Badshah Road, Sector A, Sanwer Road Industrial Area, Indore (M P ) 452015. We have two units, Unit I and Unit II, both located at Factory 12/2, Progressive Industrial Park, Tigaria Badshah Road, Sector A, Sanwer Road Industrial Area, Indore (M P ) 452015. Unit I is dedicated to forming components for electric vehicle applications, while Unit II specializes in commercial vehicle components. We are proud to offer exquisite vacuum formed components that are designed and prototyped to meet your specific needs. Our team of experts will work closely with you to ensure that your project is completed on time and within budget..