PowerPoint Presentation

Scene 1 (0s)

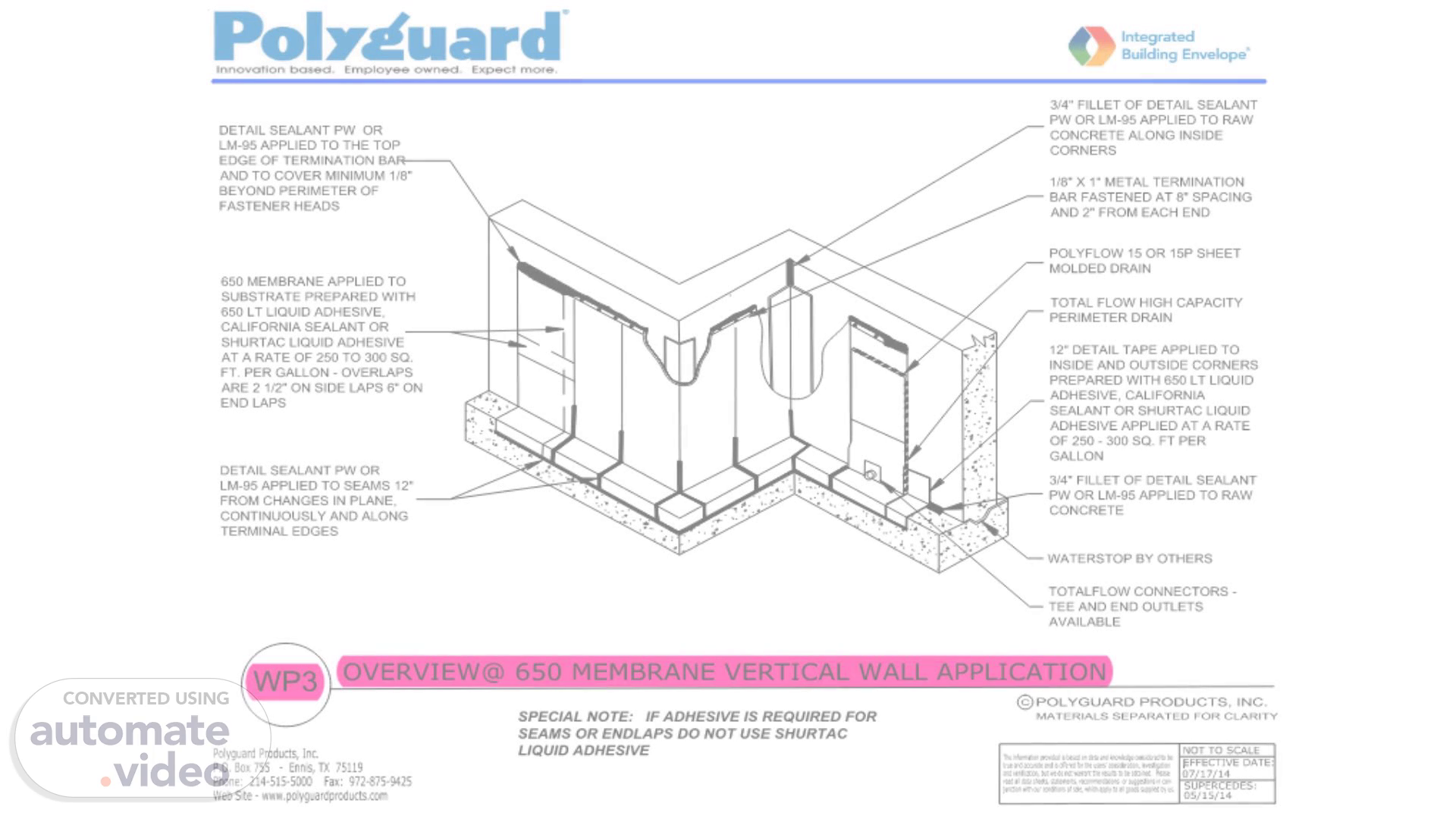

[Audio] 650 MEMBRANE Sheet Waterproofing Membrane: Please pay close attention to the manufacturer's instructions and technical specifications regarding the designated waterproof membrane system. Let's start with Installation instructions. SURFACE PREPARATION Reference: Approved submittal (Transmittal Number 00125) and Page 4. Prior to starting work, check that all horizontal surfaces to be waterproofed slope towards drainage or refer to balcony details for zero-slope applications. This material is not designed to be applied in areas where water will pond. A smooth monolithic concrete surface is required. Provide a Concrete Surface Profile (CSP) 1 thru 3. Broom surfaces are not recommended. Concrete should be dry, frost free and cured a minimum of seven days prior to application of Polyguard membrane and Liquid Adhesive. Surface must be free of voids, spalled areas, sharp projections, loose aggregate and form release agents. Do not use concrete curing compounds containing oil, wax or pigments. Form release agents must be the self-dissipating type which will not transfer to the membrane. Surface defects; such as cracks, holes, or cavities; should be filled and finished flush with a Portland cement grout or concrete. Finish below-grade (except footings) and the top of projecting ledge surfaces to a beveled or rounded edge. Concrete masonry walls or brick require a well-adhered parge coat before application of membrane. Striking off joints flush with surface is also required. Clean all surfaces to remove debris, dust and loose stones before application begins. DO NOT apply system to frozen concrete. The next item is Penetration/Inside Corner/Fillet/Detail Liquid Membrane Apply fillets formed by Detail Sealant PW, LM-95 Liquid Membrane, latex modified cement mortar or epoxy mortar at the base of foundation walls, footings, and inside corners. Provide a 3/4" fillet face. DO NOT use wood or fiber cant strips. DO NOT prime underneath Detail Sealant PW or LM-95 Liquid Membrane when applied to concrete. Cover all inside corners and the base of the foundation wall to footing joint using a 12-inch-wide strip of Detail Tape centered along the axis. Press or roll firmly to achieve a complete seal. Detail Sealant PW or LM-95 Liquid Membrane may be substituted for the initial 12-inchwide strip of Detail Tape on inside corners by applying a minimum of 90 mils, 3/4" fillet (cant) 6" vertically and horizontally away from the fillet (cant). Treat drains and projections with a second ply of 650 Membrane for a distance of 6" away from drain or projection. Seal all terminations with Detail Sealant PW or LM-95 Liquid Membrane. Complete detail work prior to mixing LM-95 Liquid Membrane. Pot life of this product is approximately 60 minutes after mixing at 70°F (21ºC). Detail Sealant PW™ an also be used, allowing a minimum 2 hours to cure prior to waterproofing membrane application. Priming for 650 MEMBRANE Stir Liquid Adhesive before use. 650 LT Liquid Adhesive, California Sealant or Shur-Tac Liquid Adhesive provides a tacky adhesive surface. 650 LT Liquid Adhesive, California Sealant or Shur-Tac Liquid Adhesive should be applied over the entire surface at a rate of 250-300 square feet per gallon. Re-prime if membrane is not applied to the Liquid Adhesive within the same working day. Use brush or sort nap lamb's wool roller for Liquid Adhesive application. Liquid Adhesive must be tacky to touch, but not wet, prior to application of 650.

Scene 2 (4m 49s)

[Audio] MEMBRANE PROTECTION/DRAINAGE BOARDS Membrane surfaces should be free of stones and dirt prior to protection board installation. When adhering protection board systems to Polyguard 650 Membrane, use a Polyguard approved adhesive system. Spot adhesion, rather than full adhesion, should be used so that in the event of backfill settlement exerting downward pressure, the protection system will detach from the membrane and slip downwards. Backfill Requirements No waiting is required before backfilling. Backfill material should be select fill: free of large dirt clods, rock, tree roots and debris. a type readily compactable upon deposit. be compacted per project specifications in 12-inch lifts. installed in lifts. not have a high water content that would cause the soil to shrink upon drying. Use mechanical compaction in horizontal layers to achieve these results. STORAGE AND HANDLING Material Handling Membrane and accessories should be unloaded and stored carefully. Protect cartons and containers from weather, sparks, flames, excessive heat, cold and lack of ventilation. DO NOT stack membrane material higher than 5-fee vertically, nor double stack pallets. Store cartons on pallets and cover to prevent water damage. For best results, store membrane above 50°F (10ºC) prior to application. Ultraviolet Protection 650 Membrane is adversely affected by ultraviolet light. Cover the waterproofing system as soon as possible; DO NOT leave exposed to sunlight for over 30 days..