Scene 1 (0s)

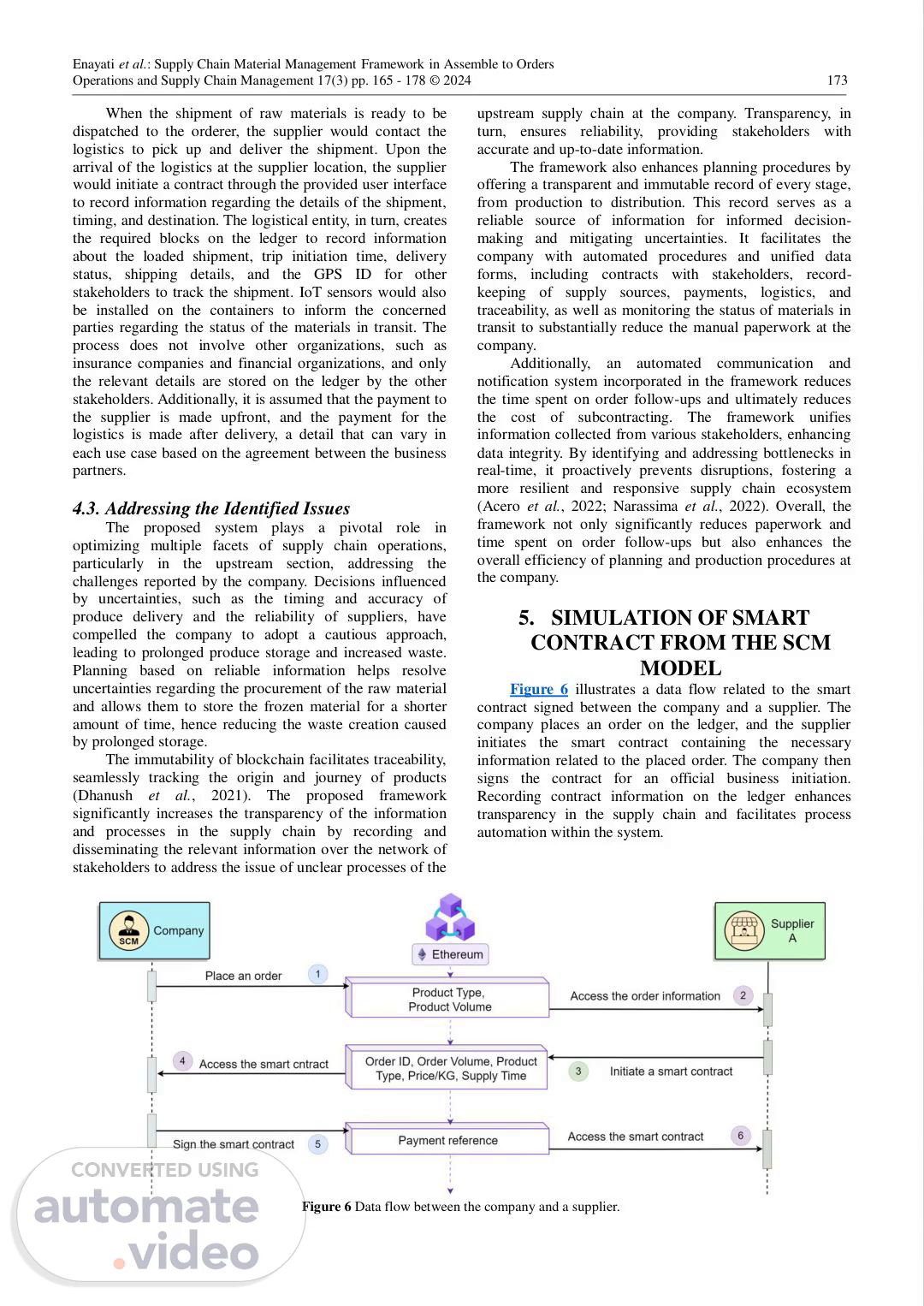

Enayati et al.: Supply Chain Material Management Framework in Assemble to Orders Operations and Supply Chain Management 17(3) pp. 165 - 178 © 2024 173 When the shipment of raw materials is ready to be dispatched to the orderer, the supplier would contact the logistics to pick up and deliver the shipment. Upon the arrival of the logistics at the supplier location, the supplier would initiate a contract through the provided user interface to record information regarding the details of the shipment, timing, and destination. The logistical entity, in turn, creates the required blocks on the ledger to record information about the loaded shipment, trip initiation time, delivery status, shipping details, and the GPS ID for other stakeholders to track the shipment. IoT sensors would also be installed on the containers to inform the concerned parties regarding the status of the materials in transit. The process does not involve other organizations, such as insurance companies and financial organizations, and only the relevant details are stored on the ledger by the other stakeholders. Additionally, it is assumed that the payment to the supplier is made upfront, and the payment for the logistics is made after delivery, a detail that can vary in each use case based on the agreement between the business partners. 4.3. Addressing the Identified Issues The proposed system plays a pivotal role in optimizing multiple facets of supply chain operations, particularly in the upstream section, addressing the challenges reported by the company. Decisions influenced by uncertainties, such as the timing and accuracy of produce delivery and the reliability of suppliers, have compelled the company to adopt a cautious approach, leading to prolonged produce storage and increased waste. Planning based on reliable information helps resolve uncertainties regarding the procurement of the raw material and allows them to store the frozen material for a shorter amount of time, hence reducing the waste creation caused by prolonged storage. The immutability of blockchain facilitates traceability, seamlessly tracking the origin and journey of products (Dhanush et al., 2021). The proposed framework significantly increases the transparency of the information and processes in the supply chain by recording and disseminating the relevant information over the network of stakeholders to address the issue of unclear processes of the upstream supply chain at the company. Transparency, in turn, ensures reliability, providing stakeholders with accurate and up-to-date information. The framework also enhances planning procedures by offering a transparent and immutable record of every stage, from production to distribution. This record serves as a reliable source of information for informed decision- making and mitigating uncertainties. It facilitates the company with automated procedures and unified data forms, including contracts with stakeholders, record- keeping of supply sources, payments, logistics, and traceability, as well as monitoring the status of materials in transit to substantially reduce the manual paperwork at the company. Additionally, an automated communication and notification system incorporated in the framework reduces the time spent on order follow-ups and ultimately reduces the cost of subcontracting. The framework unifies information collected from various stakeholders, enhancing data integrity. By identifying and addressing bottlenecks in real-time, it proactively prevents disruptions, fostering a more resilient and responsive supply chain ecosystem (Acero et al., 2022; Narassima et al., 2022). Overall, the framework not only significantly reduces paperwork and time spent on order follow-ups but also enhances the overall efficiency of planning and production procedures at the company. 5. SIMULATION OF SMART CONTRACT FROM THE SCM MODEL Figure 6 illustrates a data flow related to the smart contract signed between the company and a supplier. The company places an order on the ledger, and the supplier initiates the smart contract containing the necessary information related to the placed order. The company then signs the contract for an official business initiation. Recording contract information on the ledger enhances transparency in the supply chain and facilitates process automation within the system. Figure 6 Data flow between the company and a supplier..

Scene 2 (1m 5s)

Enayati et al.: Supply Chain Material Management Framework in Assemble to Orders 174 Operations and Supply Chain Management 17(3) pp. 165 - 178 © 2024 The following smart contract is written in Solidity programming language which is specifically coded for the Ethereum blockchain network. It is developed based on the above-mentioned business process between the company and the supplier. The supplier is required to provide necessary information related to the order, such as the order ID, volume of the ordered item in kilograms, the product name, its price per kilogram in dollars, the estimated time required to supply the product, and the digital wallet address of the company that placed the order. The cost related to the placed order will be calculated by the smart contract after being deployed by the supplier. The company is then expected to provide the payment reference number, and delivery address coordination, and sign the contract after checking the information recorded on the smart contract. // SPDX-License-Identifier: MIT pragma solidity ˆ0.8.24; contract SupplyCompanyContract modifier onlyCompany() constructor( string memory _orderId, uint256 _volume, string memory _productType, uint256 _priceKG, uint256 _supplyTime, address _companyAdd) function provideDetailsByCompany(string memory _paymentReferenceCode, string memory _deliveryCoordinates) external onlyCompany }.

Scene 3 (2m 10s)

Enayati et al.: Supply Chain Material Management Framework in Assemble to Orders Operations and Supply Chain Management 17(3) pp. 165 - 178 © 2024 175 Figure 7 Simulated smart contract on Remix IDE. Figure 8 Prevention of unauthorized access to the contract. 5.3. Limitations of the Study Similar to other studies, this research also has some limitations. The first limitation is the study’s reliance on investigating only the reported issues already identified by the company’s supply chain management department. This approach may result in an incomplete understanding of the problematic situation, as the issues could have been identified by the research team for a more rigorous investigation and a deeper understanding of the entire procedures at the company. Secondly, the authors opted for a qualitative methodology, focusing solely on the supply chain management department staff, due to constraints related to the availability of staff at the company and funding. Future studies should take a mixed-method approach adding a quantitative survey research design to generate causal inferences to identify specific indicators and to generalize the findings. Thirdly, the research team was unable to conduct interviews with all suppliers and logistics companies to align the proposed solution with their perspectives on the issues. Finally, the proposed design was not implemented due to the phased funding arrangement, the next phase of the study will involve the implementation of the proposed framework and an examination of the effectiveness of using blockchain technology to resolve the identified issues. These limitations prompt readers to approach the pro- posed solution cautiously. Future research endeavors could benefit from a more in-depth investigation of the procedures at the company under study; incorporation of a mixed- method research design to achieve a richer dataset and a more holistic perspective; collect information from all stake- holders for a deeper understanding of the problematic areas. Despite the identified limitations, the study sheds valuable insights on the benefits of utilizing blockchain technology for improving the resilience and performance of supply chain management systems. The framework proposed in the study shows significant promise as a solution. 6. CONCLUSION This study examined the supply chain management system of an Australian food processing company, to identify the challenges faced by it, and proposed a blockchain-based framework to enhance of its resilience for transparency and reliability. It makes a significant contribution in identifying the pathway to incorporate the attributes of blockchain technology in improving the resilience, traceability, transparency, and automation of the supply chain management systems in companies with manual procedures specifically in their upstream supply chain management section. To answer the first research question, the study shed light on five cases of challenges faced by the company in its supply chain management section namely a lack of reliable information for informed decision-making, excessive bureaucracy, lack of automated procedures, unknown status of the material in transit, and various formats of information provided by other stakeholders. To provide an answer to the second research question, a blockchain-based framework is proposed which takes a more holistic approach and offers a solution for the whole supply chain, rather than a piecemeal one. Upon implementation, the framework has the potential to track products through the supply chain in real time using data received from GPS tracking devices, IoT monitoring devices installed on vehicles transporting raw food materials and perishable supplies, and updated status at each checkpoint through- out the proposed supply chain design. This would enable rapid identification of faults and bottlenecks where expected progress is not observed on the developed mobile/web applications, leading to faster and more cost-efficient delivery of products, ensuring freshness, reducing waste, enhancing traceability and coordination between stakeholders, and promoting total quality by correcting the conventional supply chain management system. The framework can be easily customized to specific domains depending on the nature of the business process as well as the territory of operations. The framework can also be modified to include domestic, national, and international trade norms in order to facilitate transparency and reliability at every stage of the supply chain. Furthermore, the smart contract between the company and a supplier suggested in the proposed SCM model has been developed, simulated, and validated using the Remix online IDE. Finally, the framework recognizes and incorporates pro- visions for the United Nations Sustainable Development Goals (UNSDGs) (Nations, 2015) by ensuring that the up- graded supply chain management in the company directly contributes to four UN SDGs. It facilitates the achievement of SDG2 by supporting a more sustainable food production system (2.4) and proper functioning of the food commodity market (2.C). Additionally, it aligns with SDG8 by promoting resource efficiency in production (8.4), and with SDG9 by increasing access to ICT and communication technologies (9.C), upgrading infrastructure with sustainable technologies (9.4), and enhancing technological capabilities (9.5)..

Scene 4 (3m 15s)

Enayati et al.: Supply Chain Material Management Framework in Assemble to Orders 176 Operations and Supply Chain Management 17(3) pp. 165 - 178 © 2024 Furthermore, the framework supports SDG12 by promoting the efficient use of natural resources (12.2), reducing food loss along production (12.3), and preventing waste generation (12.5). Despite the numerous benefits of blockchain technology, it also poses certain limitations that must be addressed when applied in a specific field. While challenges like storage concerns, power consumption, technology adoption, transaction charges, scalability, and confidentiality can be mitigated during the design phase, others, such as legislative issues and oracle challenges involving data input into the ledger, require close cooperation among governments, private entities, and academia to resolve. Government policies that provide a clear legal framework for blockchain applications and encourage innovation, coupled with support from the private sector through investments in research and development, can play a pivotal role in overcoming these challenges and fostering the widespread adoption of blockchain technology. An avenue to explore in future research would be to evaluate and simulate the proposed framework and implement the solution within the actual operations of the food processing company studied. ACKNOWLEDGEMENT This research is a collaborative effort between Amrita Vishwa Vidyapeetham and Central Queensland University (CQUniversity) and is funded by the E4LIFE International Ph.D. Fellowship Program. The authors extend their heartfelt gratitude to the management and staff of a local food processing company in Bundaberg for their invaluable assistance during the data collection phase. The authors thank Dr. Sabrina F., Dr. Tariq U.U., and Dr. Gordon S. for their input to improve the quality of this study. Additionally, the authors acknowledge the help of Mr. Sai Ruthwick Madas, who assisted in interviewing some staff, collecting qualitative information, and conducting literature research. AUTHOR CONTRIBUTIONS Enayati: Conceptualization, Methodology, Formal analysis, Data Curation, Writing - Original Draft, Writing - Review & Editing, Visualization. Gudimetla: Conceptualization, Methodology, Formal analysis, Investigation, Writing - Original Draft, Writing - Review & Editing, Project administration. Arlikatti: Writing - Review & Editing. DATA AVAILABILITY The data used in this study are available upon request and following the execution of a Commercial Non- Disclosure Agreement (NDA) due to the presence of commercially sensitive information within the raw data. REFERENCES Abdul Rahman, N., Lirn, T. C., Hamid, A., & AlKalbani, K. (2023). Logistics Business Sustainability Incorporating National Logistics Strategy and Industry Revolution 4.0. Operations and Supply Chain Management: An International Journal, 16(3), pp. 341-351. Acero, B., Saenz, M. J., & Luzzini, D. (2022). Introducing Snchromodality: One Missing Link Between Transportation Sand Supply Chain Management. Journal of Supply Chain Management, 58(1), pp. 51-64. Adaryani, R. L., Palouj, M., Karbasioun, M., Asadi, A., Gholami, H., Kianirad, A., & Damirchi, M. J. (2024). Antecedents of Blockchain Adoption in the Poultry Supply Chain: An Extended UTAUT Model. Technological Forecasting and Social Change, 202, 123309. Adeusi, K. B., Adegbola, A. E., Amajuoyi, P., Adegbola, M. D., & Benjamin, L. B. (2024). The Potential of IoT to Transform Supply Chain Management Through Enhanced Connectivity and Real-Time Data. World Journal of Advanced Engineering Technology and Sciences, 12(1), pp. 145-151. Afghah, M., Sajadi, S. M., Razavi, S. M., & Taghizadeh‐Yazdi, M. (2023). Hard Dimensions Evaluation in Sustainable Supply Chain Management for Environmentally Adaptive and Mitigated Adverse Eco‐Effect Environmental Policies. Business Strategy and the Environment, 32(7), pp. 5044-5067. GS1 AISBL. (2008, May). What is GS1? [Brochure]. Retrieved September 27, 2023, from https://www.gs1.org/sites/default/files/docs/what_is_gs1.pdf Alkaabi, N., Salah, K., Jayaraman, R., Arshad, J., & Omar, M. (2020). Blockchain-Based Traceability and Management for Additive Manufacturing. IEEE access, 8, pp. 188363- 188377. Anbuudayasankar, S. P., Srikanthan, R., Karthik, M., Nair, P. R., Sivakarthik, N., & Indukumar, P. (2020). Cloud-Based Technology for Small and Medium Scale Enterprises: A Decision-Making Paradigm Using IPA, AHP and Fuzzy- AHP Techniques. International Journal of Integrated Supply Management, 13(4), pp. 335-352. Ben-Daya, M., Hassini, E., & Bahroun, Z. (2019). Internet of Things and Supply Chain Management: A Literature Review. International Journal of Production research, 57(15-16), pp. 4719-4742. Carter, C. R., & Rogers, D. S. (2008). A Framework of Sustainable Supply Chain Management: Moving Toward New Theory. International Journal of Physical Distribution & Logistics Management, 38(5), pp. 360-387. Chen, S., & Chen, Y. (2023). Designing a Resilient Supply Chain Network under Ambiguous Information and Disruption Risk. Computers & Chemical Engineering, 179, pp. 108428. Closs, D. J., & McGarrell, E. F. (2004). Enhancing security throughout the supply chain, IBM Center for the Business of Government, Washington. Cocco, L., Mannaro, K., Tonelli, R., Mariani, L., Lodi, M. B., Melis, A., ... & Fanti, A. (2021). A Blockchain-Based Traceability System in Agri-Food SME: Case Study of a Traditional Bakery. IEEE Access, 9, pp. 62899-62915. Darshan, M., Akella, S. V., Raswanth, S. R., & Kumar, P. (2022, January). A Smart IoT Based Agro-Management System Using Distributed Ledger and Circular Supply Chain Methodology. International Conference on Electrical and Electronics Engineering, 894, pp. 345-354. Das, D., Dasgupta, K., & Biswas, U. (2023). A Secure Blockchain-Enabled Vehicle Identity Management Framework for Intelligent Transportation Systems. Computers and Electrical Engineering, 105, pp. 108535. Dhanush, G. A., Raj, K. S., & Kumar, P. (2021). Blockchain Aided Predictive Time Series Analysis in Supply Chain System. Innovations in Electrical and Electronic Engineering: Proceedings of ICEEE 2021, pp. 913-925. Enayati, M., Arlikatti, S., & Ramesh, M. V. (2024). A Qualitative Analysis of Rural Fishermen: Potential for Blockchain- Enabled Framework for Livelihood Sustainability. Heliyon, 10(2), pp. 24358..

Scene 5 (4m 20s)

Enayati et al.: Supply Chain Material Management Framework in Assemble to Orders Operations and Supply Chain Management 17(3) pp. 165 - 178 © 2024 177 Enayati, M., Lekshmi, S. S., Toby, T., Prabhu, M., Rahul, K. P., Parvathy, S., & Ponnekanti, S. (2022). Blockchain-Based Location Sharing in 5g Open Ran Infrastructure for Sustainable Communities. Intelligent Sustainable Systems: Selected Papers of WorldS4 2021, 1, pp. 571-585. Fatima, N., Abrar, M., & Shahbaz, M. (2024). Untangling the Influencing Factors of Intention to Adopt Green Supply Chain Management Practices: An Integration of Toe Framework and Self-Determination Theory. Operations and Supply Chain Management: An International Journal, 17(1), pp. 104-122. Ferreira Jr, P. C. D., Machado, E. M. M., Meiriño, M. J., Quelhas, O. L. G., & Mexas, M. P. (2022). COVID-19 Pandemic: Impacts on Supply Chain Sustainability. In Handbook of Research on SDGs for Economic Development, Social Development, and Environmental Protection, pp. 113-127. Goyal, S. B., Pradeep, N., Shukla, P. K., Ghonge, M. M., & Ravi, R. V. (Eds.). (2022). Utilizing Blockchain Technologies in Manufacturing and Logistics Management, IGI Global. Guan, W., Ding, W., Zhang, B., Verny, J., & Hao, R. (2023). Do Supply Chain Related Factors Enhance the Prediction Accuracy of Blockchain Adoption? A Machine Learning Approach. Technological Forecasting and Social Change, 192, pp. 122552. Helo, P., & Shamsuzzoha, A. H. M. (2020). Real-Time Supply Chain—a Blockchain Architecture for Project Deliveries. Robotics and Computer-Integrated Manufacturing, 63, pp. 101909. Hsiao, S. J., & Sung, W. T. (2022). Blockchain-Based Supply Chain Information Sharing Mechanism. IEEE Access, 10, pp. 78875-78886. Israfilov, N., Druzyanova, V., Ermakova, M., & Sinitsyna, A. (2023). Key Directions for Transforming Supply Chain Management in Emerging Markets during the Post-COVID- 19 Pandemic Period. Operations and Supply Chain Management: An International Journal, 16(4), pp. 498-508. Issa, W., Moustafa, N., Turnbull, B., Sohrabi, N., & Tari, Z. (2023). Blockchain-Based Federated Learning for Securing Internet of Things: A Comprehensive Survey. ACM Computing Surveys, 55(9), pp. 1-43. Johnson, F., Leenders, M. R., & Flynn, A. E. (2021). Purchasing and supply management, McGraw-Hill Companies, Inc. Kovács, G., & Falagara Sigala, I. (2021). Lessons Learned from Humanitarian Logistics to Manage Supply Chain Disruptions. Journal of Supply Chain Management, 57(1), pp. 41-49. Kumar, P., Mohan, G. B., Jaikanth, Y., George, R., Vishnu, K. P., & Elakkiya, R. (2023). Agro-Ledger: Blockchain Based Framework for Transparency and Traceability in Agri-Food Supply Chains. In 2023 IEEE International Conference on Blockchain and Distributed Systems Security (ICBDS), pp. 1-6. Levitt, T. (1983). The Globalization of Markets, Graduate School of Business Administration, Harvard University, Boston. Liu, L., Song, W., & Liu, Y. (2023). Leveraging Digital Capabilities Toward a Circular Economy: Reinforcing Sustainable Supply Chain Management with Industry 4.0 Technologies. Computers & Industrial Engineering, 178, pp. 109113. Mardiansyah, V., & Sari, R. F. (2022). Lightweight Blockchain Framework for Medical Record Data Integrity. Journal of Applied Science and Engineering, 26(1), pp. 91-103. McAleavy, T. (2020). Perceiving the Effects of Scale on Command and Control: A Conceptual Metaphor Approach. J. Emerg. Manag, 18(2), pp. 91-104. Misra, N., Gupta, S., Sidhu, K. S., Kumar, A., Anandaram, H., Rao, T. J., ... & Joshi, K. (2023). Role of Blockchain Technology Integration for Green Bonds Issuance with Sustainability Aspect. International Journal on Recent and Innovation Trends in Computing and Communication, 11(06), pp. 134-142. Molano, J. I. R., Bravo, L. E. C., & Trujillo, E. R. (2017). Supply Chain Architecture Model Based in the Industry 4.0, Validated through a Mobile Application. Contemporary Engineering Sciences, 10(32), pp. 1581-1594. Musamih, A., Salah, K., Jayaraman, R., Arshad, J., Debe, M., Al- Hammadi, Y., & Ellahham, S. (2021). A Blockchain-Based Approach for Drug Traceability in Healthcare Supply Chain. IEEE access, 9, pp. 9728-9743. Nair, P. R. (2012). High Performance & Cloud Computing Interventions for Supply Chain Management. CSI Communications, 37(6), pp. 13-14. Nair, P. R., & Anbuudayasankar, S. P. (2016). An Investigation on the Benefits of ICT Deployment in Supply Chain Management (SCM). Indian Journal of Science and Technology, 9(30), pp. 1-7. Nair, P. R., & Anbuudayasankar, S. P. (2016). Tackling Supply Chain Management through RFID: Opportunities and Challenges. In Proceedings of the International Congress on Information and Communication Technology: ICICT 2015, 1, pp. 467-475. Nakamoto, S., & Bitcoin, A. (2008). A Peer-To-Peer Electronic Cash System. Bitcoin.–URL: https://bitcoin. org/bitcoin. pdf, 4(2), 15. Narassima, M. S., Anbuudayasankar, S. P., Mathiyazhagan, K., Ganesh, K., & Lee, T. R. (2024). Supply Chain Resilience: Conceptual Model Building and Validation. International Journal of Logistics Research and Applications, 27(5), pp. 781-813. Nations, U. (2015). Transforming Our World: The 2030 Agenda for Sustainable Development. New York: United Nations, Department of Economic and Social Affairs, 1, pp. 41. OBAID, M., OBAID, M., & AQEL, M. (2021). Mobile Payment using Blockchain Security. Pagell, M., & Shevchenko, A. (2014). Why Research in Sustainable Supply Chain Management Should Have No Future. Journal of Supply Chain Management, 50(1), pp. 44-55. Paliwal, V., Chandra, S., & Sharma, S. (2020). Blockchain Technology for Sustainable Supply Chain Management: A Systematic Literature Review and a Classification Framework. Sustainability, 12(18), pp. 7638. Perboli, G., Musso, S., & Rosano, M. (2018). Blockchain in Logistics and Supply Chain: A Lean Approach for Designing Real-World Use Cases. IEEE Access, 6, pp. 62018-62028. Salah, K., Nizamuddin, N., Jayaraman, R., & Omar, M. (2019). Blockchain-Based Soybean Traceability in Agricultural Supply Chain. IEEE Access, 7, 73295-73305. Seitz, M. A., & Wells, P. E. (2006). Challenging the Implementation of Corporate Sustainability: The Case of Automotive Engine Remanufacturing. Business Process Management Journal, 12(6), pp. 822-836. Seuring, S., & Müller, M. (2008). From a Literature Review To a Conceptual Framework for Sustainable Supply Chain Management. Journal of cleaner production, 16(15), pp. 1699-1710. Shetu, S., & Karim, M. R. (2023). COVID-19, Supply Chain, and Profitability: A Survey Based on an Emerging Economy. Operations and Supply Chain Management: An International Journal, 16(1), pp. 1-15. Singh, A. K., Kumar, V. P., Dehdasht, G., Mohandes, S. R., Manu, P., & Rahimian, F. P. (2023). Investigating Barriers to Blockchain Adoption in Construction Supply Chain Management: A Fuzzy-Based MCDM Approach. Technological Forecasting and Social Change, 196, pp. 122849..

Scene 6 (5m 25s)

Enayati et al.: Supply Chain Material Management Framework in Assemble to Orders 178 Operations and Supply Chain Management 17(3) pp. 165 - 178 © 2024 Singh, V., & Sharma, S. K. (2023). Application of Blockchain Technology in Shaping the Future of Food Industry Based on Transparency and Consumer Trust. Journal of Food Science and Technology, 60(4), pp. 1237-1254. Smith, B. G. (2008). Developing Sustainable Food Supply Chains. Philosophical Transactions of the Royal Society B: Biological Sciences, 363(1492), pp. 849-861. Sodhi, M. S., & Tang, C. S. (2021). Supply Chain Management for Extreme Conditions: Research Opportunities. Journal of Supply Chain Management, 57(1), pp. 7-16. Suban, I. B., & da Costa, J. E. (2021, April). Mobile Application Design of Smart Water Supply Chain Based on IoT: A Case Study in Indonesia. In IOP Conference Series: Earth and Environmental Science, 729(1), pp. 012010. Thompson, B. S., & Rust, S. (2023). Blocking Blockchain: Examining the Social, Cultural, and Institutional Factors Causing Innovation Resistance to Digital Technology in Seafood Supply Chains. Technology in Society, 73, pp. 102235. Tokar, T., & Swink, M. (2019). Public Policy and Supply Chain Management: Using Shared Foundational Principles to Improve Formulation, Implementation, and Evaluation. Journal of Supply Chain Management, 55(2), pp. 68-79. Trivedi, S. (2023). Blockchain Framework for Insurance Industry. International Journal of Innovation and Technology Management, 20(06), pp. 2350034. Wang, Z. J., Chen, Z. S., Xiao, L., Su, Q., Govindan, K., & Skibniewski, M. J. (2023). Blockchain Adoption in Sustainable Supply Chains for Industry 5.0: A Multistakeholder Perspective. Journal of Innovation & Knowledge, 8(4), pp. 100425. Zhang, X., Sun, P., Xu, J., Wang, X., Yu, J., Zhao, Z., & Dong, Y. (2020). Blockchain-Based Safety Management System for the Grain Supply Chain. IEEE Access, 8, pp. 36398-36410. Zhu, Q., Sarkis, J., & Geng, Y. (2005). Green Supply Chain Management in China: Pressures, Practices and Performance. International Journal of Operations & Production Management, 25(5), pp. 449-468. Mr. Mojtaba Enayati obtained his B.S. in computer hardware from Shomal University, Iran, followed by a Master of Computer Application from Savitribai Phule Pune University, India, in 2014. Currently, he is in the final year of his Ph.D. in Sustainable Development at Amrita Vishwa Vidyapeetham, India, with a primary focus on blockchain technology. His research endeavors revolve around leveraging blockchain technology to enhance sustainability and resilience among fisherfolk in rural Indian communities. He is particularly intrigued by the development of sustainable blockchain-based solutions aimed at fostering a more resilient digital ecosystem. Professor Prasad Gudimetla is a Mechanical Engineering with a PhD in Advanced Manufacturing. He has worked as a researcher, academic, and consultant for over 25 years in Australia and specializes in product and process optimization for various manufacturing industries such as Boeing Australia, Dahar Australian Aerospace, Rover, Ford Motors, EGR Plastics, etc. He is also a trained biomechanical engineer and works at the interface of mechanical, medical, and advanced manufacturing engineering domains. He has published widely in these domains. His focus is on developing innovative and sustainable engineering solutions for the industry to entail higher productivity by economizing processes and services. Professor Sudha Arlikatti has degrees in Architecture from Pune University, City Planning from I.I.T. Kharagpur, and Urban and Regional Science from Texas A& M University with an emphasis in Environmental Planning and Hazards Management. She has over 12 years of practitioner experience and 19 years of teaching and research experience in the USA, India, and the UAE. Her research interests include risk communication and protective action decision- making in multi-ethnic communities responding to tsunamis, floods, earthquakes, hurricanes, and biological threats; disaster sheltering and housing recovery; and individual and organizational resiliency for sustainable development. She has received funding for her research endeavors from the U.S. National Science Foundation, Texas Department of State Health Services, Dallas Area Habitat for Humanity, and the University of North Texas. View publication stats.