Scene 1 (0s)

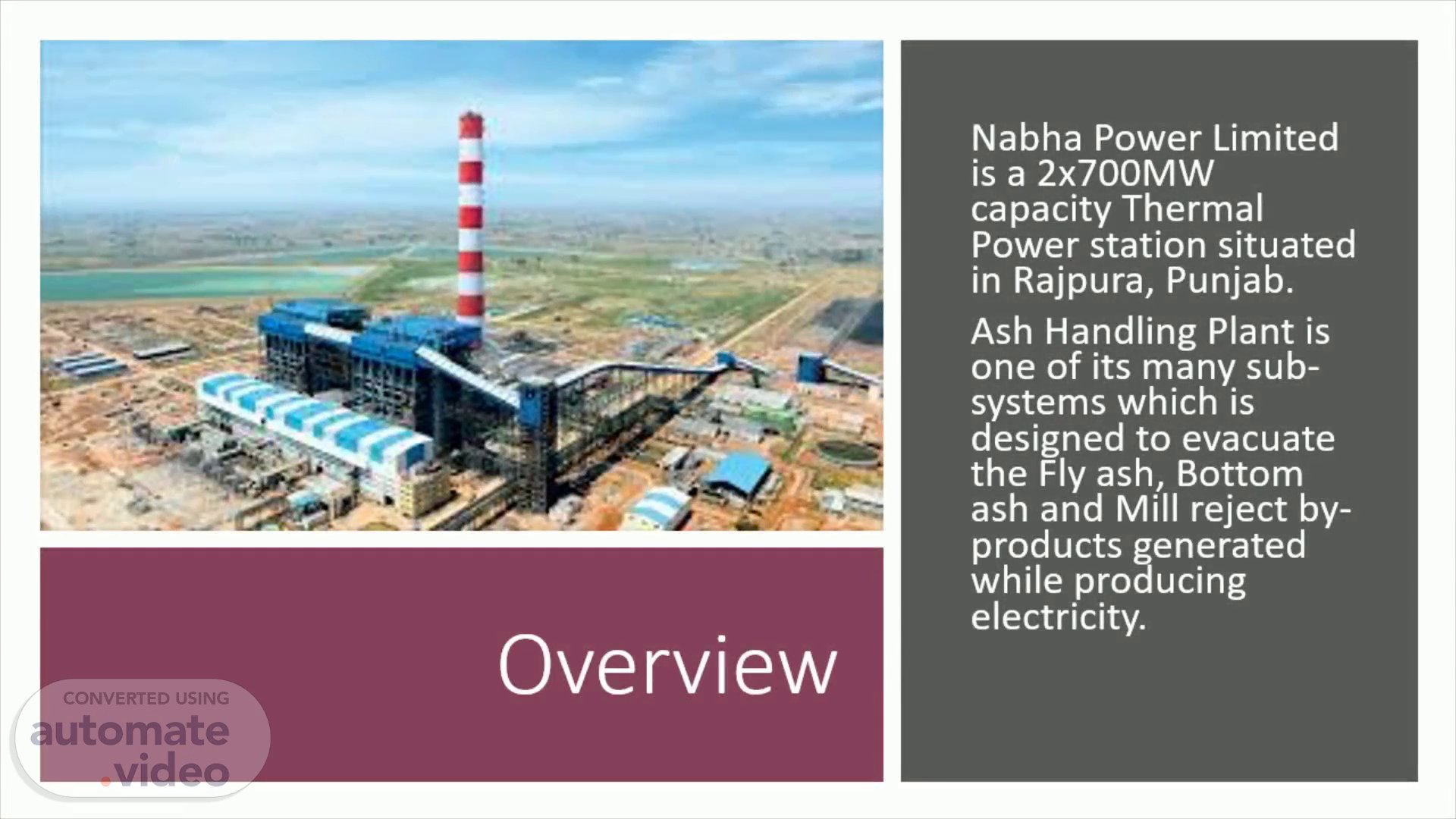

[Audio] Nabha Power Limited is a 2x700MW capacity Thermal Power station situated in Rajpura, Punjab. Ash Handling Plant is one of its many sub-systems which is designed to evacuate the Fly ash, Bottom ash and Mill reject by- products generated while producing electricity..

Scene 2 (21s)

[Audio] The purpose of this SOP is to provide guidelines for normalization of AHP Equipment in case of Power failure in Ash Handling Plant or if Station Blackout takes place..

Scene 3 (33s)

[Audio] The scope is to Ensure Uninterrupted Boiler operation during Power failure in AHP. Checking and maintaining of Seal trough level or checking any abnormality in system during Power failure maintaining level in the Bottom Ash hopper, Eco Hopper isolation and normalization or restart or whether the start-up of various drives while Resuming the Fly ash and Bottom ash evacuation after checking healthiness of evacuation system..

Scene 4 (1m 1s)

[Audio] Shift In- charge is responsible for compliance with this S.O.P. The concerned Shift In-charge and AHS desk engineer will execute the work as per the procedure laid down..

Scene 5 (1m 14s)

[Audio] Locations for which this S.O.P. applies are: Bottom ash hopper area, Eco Hoppers, Ash Water Pump House, Ash Slurry Pump House and Fly Ash Extraction Towers..

Scene 6 (1m 30s)

[Audio] Here on we will discuss the procedure to be carried out, during the blackout or power failure, and what to do later to resume the system when power is normalized..

Scene 7 (1m 45s)

[Audio] Activities or Actions to be taken when a blackout, or power failure occurs, are given as follows in a step-by-step manner to ensure all redundancies are covered..

Scene 8 (2m 0s)

[Audio] Ensure that Service water line to seal trough is charged from Main Plant, to ensure sealing between boiler and bottom ash hopper in case of AHP power failure. Seal trough to be charged from firefighting line in case of Station Blackout..

Scene 9 (2m 17s)

[Audio] Ensure that bottom ash feed-gate is closed and conveying line discharge Valves are in open condition, note that this is only applicable if Bottom ash evacuation is in running condition..

Scene 10 (2m 30s)

[Audio] Eco Hopper Knife gate valves are to be closed at once, and ensure water level is maintained in seal expansion tank..

Scene 11 (2m 41s)

[Audio] Ensure that Service water or Firefighting line water is charged, after closing ECO Hopper isolation Valve through Eco Hopper Flushing Apparatus, for Bottom ash hopper make-up to ensure hopper overflow is maintained, and water temperature is maintained below 60 Degree Celsius through Eco Hopper Flushing Apparatus in case of Station Blackout.

Scene 12 (3m 3s)

[Audio] Ensure availability of instrument air by opening the interconnection valves after communicating to CCR..

Scene 13 (3m 13s)

[Audio] Ensure that DC Supply is uninterrupted for PLC system from UPS from one of the three sources: either Primary, Secondary or the Battery bank. As displayed on UPS panel in AHP Control Room. (During failure of Primary supply Secondary takes over, in case of failure of both primary and secondary sources battery bank is used to draw power temporarily.).

Scene 14 (3m 41s)

[Audio] Ensure Slurry series suction and discharge valves need to be in open condition after power failure, or station Blackout Occur during Bottom Deashing..

Scene 15 (3m 54s)

[Audio] Activities or Actions to be taken after Power failure is rectified and power is restored, now the task at hand, is to check and verify if power supply to all drives is normalized, so that system can be restored to normal working conditions..

Scene 16 (4m 11s)

[Audio] Normalize the availability of 415Volts & 3.3kv, 3 phase, 50 hertz supply for motors.

Scene 17 (4m 22s)

[Audio] Normalize the availability of 240Volts-single phase- 50hertz supply for UPS.

Scene 18 (4m 32s)

[Audio] Normalize the availability of 24Volts DC & 220Volts DC supply for PLC & breaker control.

Scene 19 (4m 42s)

[Audio] Activities or Actions to be taken after Power failure is rectified and power is restored, now the task at hand is to normalize the system, and restore it to normal working conditions..

Scene 20 (4m 58s)

[Audio] After normalization of electrical supply follow SOP of each drive to normalize the system.

Scene 21 (5m 7s)

[Audio] Normalize seal trough make up from BALP. Refer concerned S.O.P. for the same..

Scene 22 (5m 17s)

[Audio] Normalize bottom ash makeup from BALP.. Normalize bottom ash makeup from BALP..

Scene 23 (5m 24s)

[Audio] Normalize Eco hoppers deashing. Refer concerned S.O.P. for the same..

Scene 24 (5m 34s)

[Audio] Normalize ESP evacuation as per SOP. Refer concerned S.O.P. for the same..

Scene 25 (5m 44s)

[Audio] Normalize Bottom Ash Hopper Evacuation system and slurry transfer system if during AHP Power failure or station Blackout, Bottom ash evacuation was in running condition, Refer concerned S.O.P. for the same..