Scene 1 (0s)

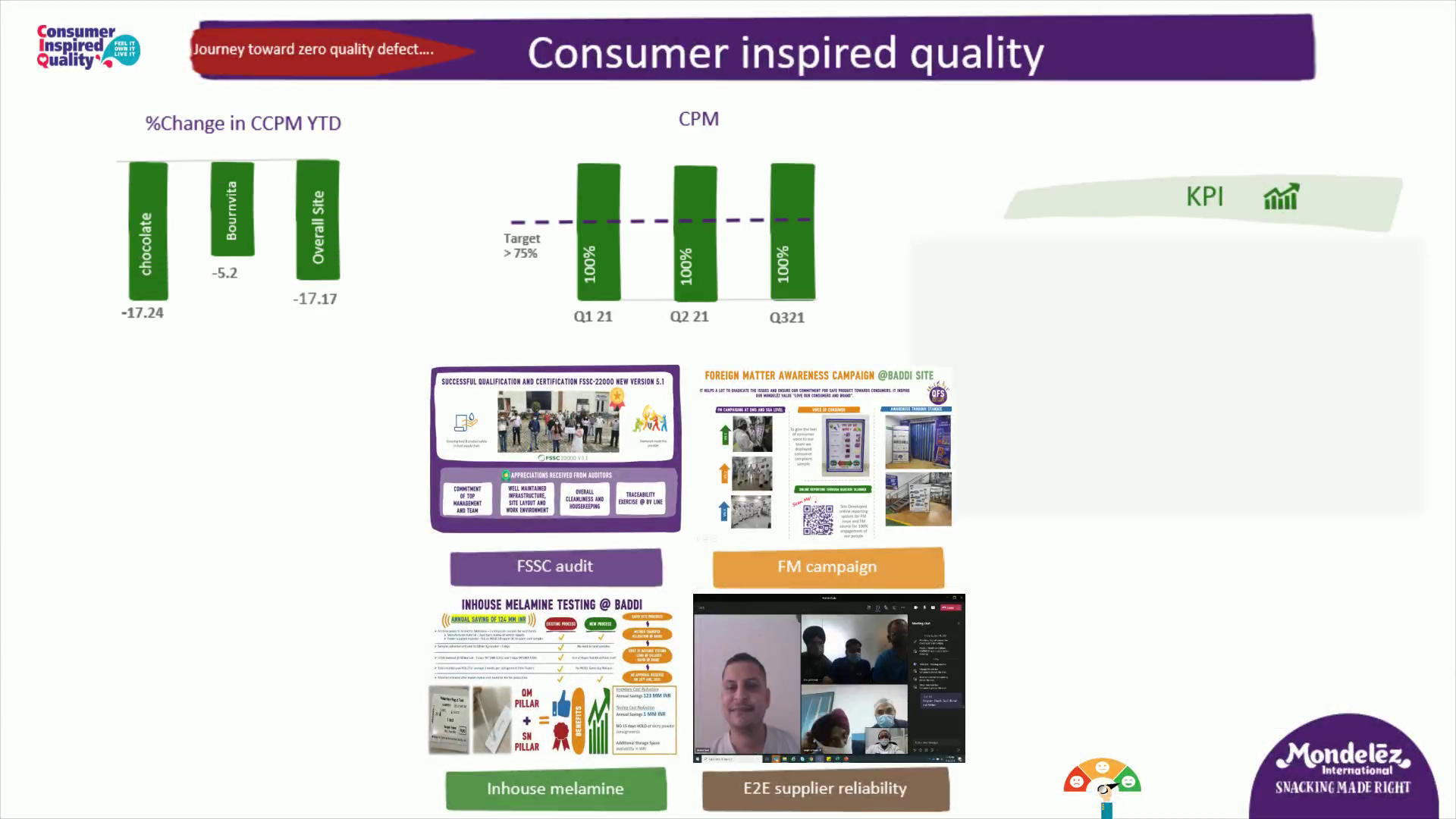

- 5 .2 - 17 .24 chocolate Overall Site -17 .17 %Change in CCPM YTD.

Scene 2 (51s)

POLLUTED BY. smQE.USE PLASTIC. Our planet is drowning in plastic pollution—it's time for change!.

Scene 3 (1m 42s)

Covid-19 awareness and preparedness plan third wave.

Scene 4 (2m 25s)

Successfully Achieved MTBB >330 Hrs. for plant in 2021-Enabled by Design Correction in Ovens, Cooler Refurbishment, Utility Equipments Overhauling. 2 Team is Strongly moving from TBM to CBM with PM step 4 Implementation. Strong focus on customer inspired Quality by Making Corrections in Equipment Design, Piping Designs, Equipment Overhauling and improving overall Plant Building Infra. 4. Baddi PM Team successfully written off old assets and Spares worth of 1.5 Cr..

Scene 5 (2m 47s)

New pipeline installation. E2E pipeline replaced for all 20 oven (vacuum line) Process water new pipeline installed at unit 1 & 2 tank farm Water treatment(Required pipeline) and maida pipeline replaced.

Scene 6 (2m 59s)

Roof preventive measure. Objective Water seepage treatment in RCC roof. Strengthen food safety compliance by elimination of rainwater seepage risk..

Scene 7 (3m 28s)

Temperature Monitoring Infrared thermography is the science of detecting infrared energy emitted from an object, converting it to an apparent temperature, and displaying the result as an infrared image that is captured by a thermal camera..

Scene 8 (3m 47s)

REGULATORY & STATUTORY COMPLIANCES. Total Compliance Complied Not complied In progress 38 36 0 2.

Scene 9 (4m 13s)

COMPLIANCE CONSCIOUS CULTURE @mondelez - LET’S MAKE it REAL.