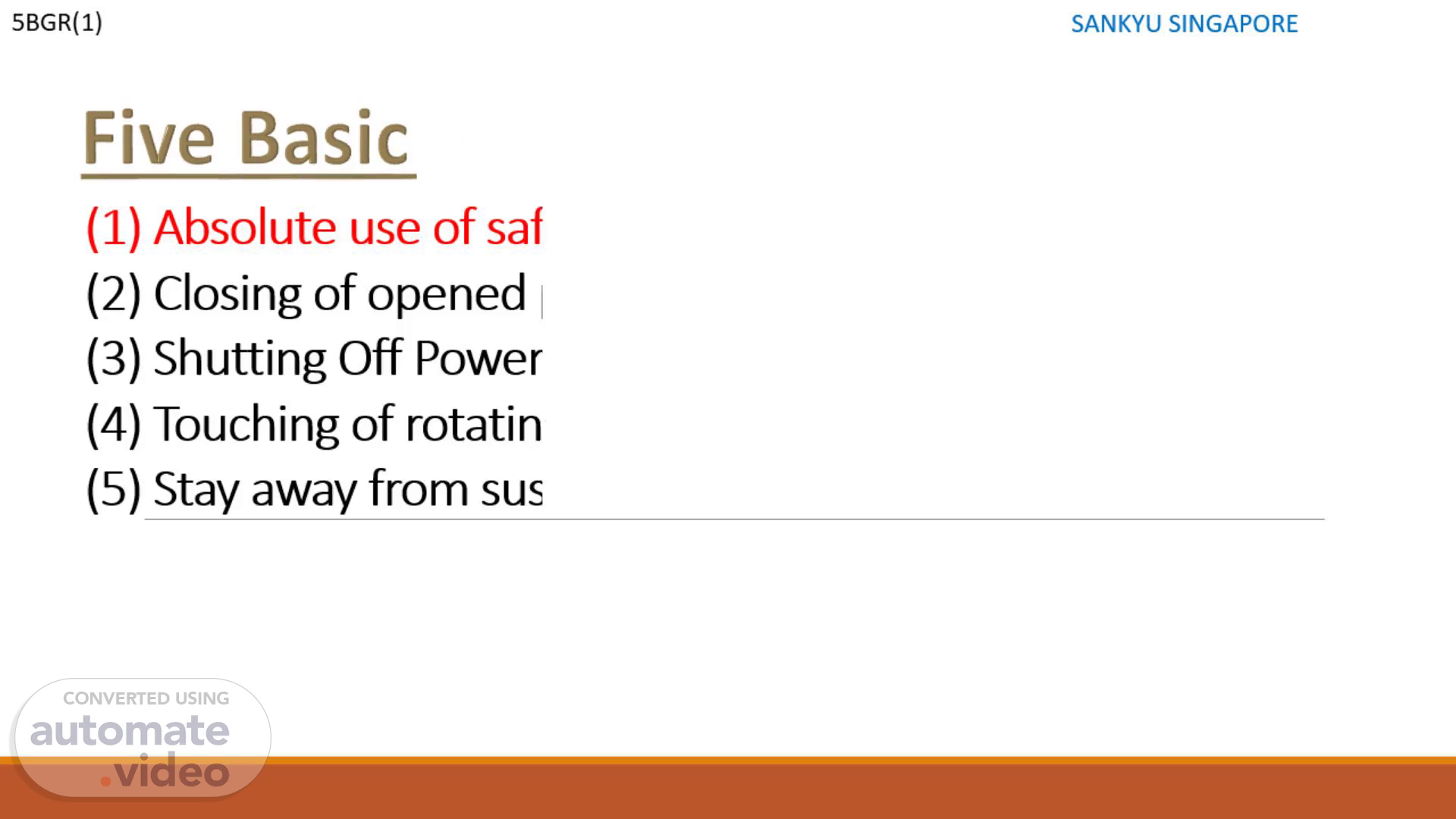

(1) Absolute use of safety harness (2) Closing of opened parts (3) Shutting Off Power when entering operating equipment (4) Touching of rotating body is Strictly Prohibited (5) Stay away from suspende

Scene 1 (0s)

(1) Absolute use of safety harness (2) Closing of opened parts (3) Shutting Off Power when entering operating equipment (4) Touching of rotating body is Strictly Prohibited (5) Stay away from suspended load.

Scene 2 (33s)

Fall Prevention Plan (FPP) for Working At Height (WAH).

Scene 3 (45s)

Introduction. Working at heights presents significant risks and challenges, necessitating stringent safety measures to protect workers from potential falls and injuries. Recognizing these dangers, it's crucial for both employers and employees to adhere to comprehensive safety standards and practices. This presentation delves into the critical aspects of work at height safety, covering definitions, responsibilities, regulations, training, permit-to-work systems, and fall control measures. By providing an in-depth exploration of these topics, we aim to equip MSC members (and stakeholders) with the knowledge and tools necessary to ensure a safe working environment for all personnel involved in work at height activities..

Scene 4 (1m 35s)

Objective. 1. Safety awareness for supervisor, foremen and worker doing work at height 2. Understanding of what is fall prevention plan and it’s need 3. Safety Harness and anchor point equipment 4. Identify what sort of equipment that use for work at height activity 5. Understand the legal , roles and responsibilities 6. Q&A 7. QR Assessment (total 15Q).

Scene 5 (1m 54s)

Definition of work at height. What is Work at Heights? Work at heights is defined as : in an elevated workplace from which a person could fall, near a floor opening through which a person could fall, near an open edge over which a person could fall, on a fragile surface through which a person could fall, or in any other place (whether above or below ground) from which a person could fall from one level to another and the person or other person would be injured due to the distance of the fall. a distance of more than 3 metres (ref: WSH Act WAH Regulations) Work at heights can result in serious workplace injuries and even death if the necessary safety measures are not in place. (Section 7 mentioned “It shall be duty of the responsible person of any person who carries out or is to carry out any work at height to ensure that the person shall work at height in a workplace under the immediate supervision of a competent person for that work).

Scene 6 (2m 34s)

Q). Scaffold, Tower Scaffold , Gondola MEWPs Scissor lift, VNA Boom lift, Men Cage Vertical platform.

Scene 7 (2m 49s)

What is Hazardous Work at Height. Hazardous work at height distinguishes itself by the increased risk it presents, specifically where falls from heights of more than 3 meters are possible. This category includes working: In or on elevated workplaces with significant fall risks. Close to openings or edges that pose fall hazards. On surfaces with a risk of breakthrough, leading to falls. In areas (above or below ground) where falls from significant heights can occur..

Scene 8 (3m 27s)

Roles and responsibilities. Supervision: A competent person should be appointed to provide proper and adequate supervision for workers to ensure that they are not exposed to hazards and all reasonable precautions have been taken where there is a risk of falling. Supervision is especially important if the workers are undergoing training, or are new or inexperienced and unfamiliar with the working environment. It is essential that persons performing supervisory roles must be competent and have the skills and knowledge of the work processes that they are to supervise..

Scene 9 (4m 4s)

Roles and responsibilities. Main Contractor's site management shall be responsible for implementation of this Fall Prevention Plan that involves its direct workforce while the management of any subsidiary or sub-contractor on site for implementation of this Fall Prevention Plan that involves their respective employees : Ensure that only trained individuals are assigned works at height that require the use of Fall Prevention systems. Ensure that appropriate and adequate equipment is purchased, and made available for personnel performing works at height Assure personnel compliance with the Fall Prevention Policy Apply Permit to work and before work commence.

Scene 10 (4m 29s)

Roles and responsibilities. WSH Officer, WSH Coordinator(s) and WSH Supervisor(s) at the project site: Assist in the development, updating and delivery of the Fall Prevention Training Programme; Maintain all Fall Prevention training and PPE issue records; Conduct independent inspection of works at height thereby contributing to improvement in Fall Prevention activities through regular monitoring; and Investigate and document incidents relating to works at height that result in workplace injury or near misses..

Scene 11 (4m 50s)

Roles and responsibilities. Site Personnel / Employees: Comply with the Fall Prevention Policy and its associated Fall Prevention Plan, as applicable; Follow the instructions of the immediate superior pertaining to Fall Prevention; Bring to the management's attention of any unsafe or hazardous conditions or practices that may cause injury to oneself or the co-workers; and Report any incident occurred during works at height that resulted in an injury to person(s)..

Scene 12 (5m 11s)

Employers are tasked with the safety of employees working at height, which involves: Conducting risk assessments to identify potential hazards. Implementing control measures to mitigate risks. Ensuring WAH activities are planned, supervised, and executed by competent personnel. Providing and maintaining access equipment and fall protection systems. Adhering to regulations and guidelines from the Ministry of Manpower and the Workplace Safety and Health Council..

Scene 13 (5m 31s)

Permit-to-Work System. Employer Responsibility: Implementing a permit-to-work system is a critical control measure for high-risk WAH activities. This system ensures that work is carried out safely and only after the necessary safety checks and authorizations have been completed..

Scene 14 (5m 47s)

Development, Monitoring, and Review. A competent person must develop the FPP, with approval from an authorized manager or equivalent. It requires adequate supervision to ensure its implementation, along with periodic monitoring and review to maintain its relevance and effectiveness..

Scene 15 (6m 9s)

What is fall prevention plan?. A site-specific plan prepared by a competent person for the purpose of reducing or eliminating the risk of falls by ensuring that all reasonable fall prevention measures and methods have been implemented, prior to the commencement of work..

Scene 16 (6m 24s)

Work At Height Regulations. When performing work at height (WAH) duties, both employers and employees must adhere to specific regulations to ensure the safety and well-being of all involved. These requirements are designed to minimize risks and provide a structured approach to managing WAH activities safely. The key components include:.

Scene 17 (10m 55s)

Fall Prevention Plan. Under Workplace Safety and Health (Work at Heights) Regulations 2013 Section 5.—(1) It shall be the duty of the occupier of every workplace specified in the Schedule, and in which work at height is carried out, to establish and implement a fall prevention plan. (2) The fall prevention plan referred to in paragraph (1) shall be established and implemented in accordance with the requirements of the approved code of practice relating to safe and sound practices for fall prevention. (4) Any occupier of a workplace specified in the Schedule who contravenes paragraph (3) shall be guilty of an offence and shall be liable on conviction to a fine not exceeding $10,000. (5) This regulation shall apply only to work at height carried out on or after 1st May 2014..

Scene 18 (11m 27s)

What are the trainings needed for Work at Heights?.

Scene 19 (11m 47s)

The MWAH course is designed for managers, supervisors, and foremen who are responsible for overseeing and managing work at height activities. The curriculum covers: Understanding the Risks: Participants are educated on the nature of fall hazards and the potential consequences of falls, emphasizing the importance of preventing such incidents. Regulatory Requirements: A comprehensive overview of legal obligations, standards, and best practices related to work at height activities. Risk Assessment and Planning: Training in conducting risk assessments, developing fall prevention plans, and implementing safety measures effectively. Use of Safety Systems and Equipment: Detailed instructions on selecting, using, and maintaining fall prevention and fall arrest systems. Emergency Preparedness: Procedures for emergency response, including rescue plans and first aid measures..

Scene 20 (12m 22s)

The PWAH course targets workers who directly engage in work at height activities, focusing on practical skills and knowledge to perform their tasks safely. Key aspects of the course include: Hazard Recognition: Teaching workers to identify and understand the hazards they face while working at heights. Control Measures: Instruction on the appropriate control measures, safe work procedures (SWPs), and the correct use of personal protective equipment (PPE). Equipment Proficiency: Ensuring workers can correctly use, inspect, and maintain work at height equipment to prevent malfunctions or failures. Emergency Actions: Training on what to do in case of an accident or emergency, including self-rescue techniques and aiding others in distress..

Scene 21 (12m 54s)

Training for Persons at Work. Employer Responsibility: Employers must ensure that all employees receive proper training relevant to their WAH tasks. This includes training on the use of equipment, understanding of safety procedures, and recognition of hazards..

Scene 22 (13m 14s)

Example of working at height work. Examples of an elevated work lace from which a Scaffod without proper guardrails and access rson could fall Top of ISO tank Work on roof.

Scene 23 (13m 29s)

Example of working at height work. Examples of an open edge over which a person could fall Open eØe Of building un±r construction without Open Of mezzanine floor without proper barricades.

Scene 24 (13m 49s)

What caused the fall ?. Absence of risk assessment prior to work commencement Absence of safe work procedure Lack of proper supervision Inadequate training Failure to observe safety rules and practices.

Scene 25 (14m 5s)

What caused the fall ?. 4 Work within the work platform. DO NOT climb or stretch out over the guard rails..

Scene 26 (14m 21s)

What caused the fall ?. Bent / twisted Stile Detached Rung Broken Rung DO NOT stand ladder on loose material. Ensure that ladder is secured firmly in place. Broken Stile DO NOT use defective ladders. Ensure that ladders are checked before use..

Scene 27 (14m 41s)

DO NOT move a mobile scaffold when somebody is on it..

Scene 28 (14m 54s)

What caused the fall ?. DO NOT use scaffolds without top and/or mid guardrails. Check that scaffolds are tagged and certified safe by Scaffold Supervisor before use..

Scene 29 (15m 8s)

What caused the fall ?. Sankyu Singapore. 5BGR(1).

Scene 30 (15m 15s)

What caused the fall ?. www.usmra.cotVre—to ge:asp oa NöT O NOTA M.

Scene 31 (15m 25s)

Video. Video on Safe Work At Height Training. Sankyu Singapore.

Scene 32 (17m 41s)

CASE STUDY 1. FALL THROUGH AN OPEN SIDE Description of Accident: Worker A and his co-worker were getting ready to carry out plastering work to a column on the fifth level of a building at a worksite. Subsequently Worker A was seen falling through the open side next to the column to be plastered. He landed on the ground level 15m below and died subsequently..

Scene 33 (18m 3s)

CASE STUDY 1. Causes and Contributing Factors: 1. The open side where the worker fell off was not barricaded. 2. There was a lot of building materials, wooden pallets, formwork materials and other materials placed on the floor on the fifth level. These materials were placed haphazardly and obstructed access. Worker A had to manoeuvre his way through these materials to his workplace.

Scene 34 (18m 25s)

CASE STUDY 2. HIT BY A RUBBER HOSE Description of Accident: A concrete pump operator and his co-workers were carrying out cleaning work on a platform which was erected about 10m above the bottom of the shaft. The cleaning work was carried out by means of inserting a sponge ball into one end of the pipeline and feeding the pipeline with compressed air. The other end of the pipeline was equipped with a rubber hose to discharge the leftover concrete into a container. The workers were gripping the rubber hose while the pump operator held down the rubber hose with a steel tube. When the sponge ball was forced out from the rubber hose, the hose swung suddenly and hit the pump operator. He was flung off the platform and landed on the bottom of the shaft. He died on the spot..

Scene 35 (19m 0s)

CASE STUDY 2 (con’t). Cause and contributing Factors: There were some pieces of timber placed on the platform where the cleaning work was carried out. Workers mentioned that it had, to some extent, hampered their work. Investigations revealed that the rubber hose was not secured in position to prevent it from moving during the cleaning operation. Towards the end of the cleaning operation, particularly at the time when the sponge ball was forced out from the hose, the sudden release of the compressed air probably created some lateral forces. This caused the hose to swing and resulted in the workers losing their grip on the hose..

Scene 36 (19m 36s)

CASE STUDY 2 (con’t). Cause and contributing Factors: 4. The hose swung and hit the pump operator, pushing him over the guardrail..

Scene 37 (19m 49s)

CASE STUDY 3. FALL OFF A TOPPLING SCAFFOLD Description of Accident: A worker was assigned to service some roof painting work at a building. He was erecting a mobile scaffold along a corridor at the fourth storey of the building when the scaffold toppled. As a result, the worker fell off from the scaffold and out of the building onto the ground 12m below..

Scene 38 (20m 15s)

CASE STUDY 3 (con’t). Causes and Contributing Factors The mobile scaffold (with a cantilevered structure) was not in a stable position and was not secured to the building structure or metal railing along the building corridor at the time of accident. When the worker climbed onto the mobile scaffold to tie the metal decking to the cantilevered structure, the mobile scaffold toppled and the worker fell off from the scaffold and building..

Scene 39 (20m 37s)

CASE STUDY 4. FALL THROUGH A ROOF Description of Accident: A worker was installing lifelines on a pitched roof at a worksite. He stepped on one of the roof tiles which then broke under his weight. The worker suffered severe head and chest injuries and eventually succumbed to the injuries..

Scene 40 (20m 56s)

CASE STUDY 4 (con’t). Causes and Contributing Factors When the worker went up the roof to install the lifelines, he had stepped onto the midsection of the roof tiles where there was no support structure. The roof tile hence broke under his weight. He fell from a height of 4.8m through the roof..

Scene 41 (21m 15s)

Video. Sankyu Singapore. 5BGR(1). Full body harness – 100% tie-off.

Scene 42 (26m 15s)

Fall Prevention Systems. The key components of every PERSONAL FALL ARREST SYSTEM ANCHORAGE A secure point of attachment (structure) for the fall arrest system. Commonly referred to as a tie-off point (ex. l.beam). BODY SUPPORT Full body harnesses provide a connection point on the worker for the personal fall arrest system. CONNECTORS Devices used to connect the worker's full body harness to the anchorage system (eg. shock absorbing lanyard, self retracting lifeline, etc.)..

Scene 43 (26m 37s)

't' 10. Safety Precaution. 1. Before working at height : apply for PTW 2. Brief worker on the risk assessment 3. Make sure that worker that work at height are train 4.For Scaffold , scissors lift , MEWP are certified by PE 5.Check safety harness ( checklist).

Scene 44 (26m 55s)

Safety Harness. Label A An labels and with Strone W.b : End Chest reduce abrasion the rrera •we. Padded Ben: Increases rt and worker.

Scene 45 (27m 6s)

How to Put on a Safety Harness. What to check for on safety harness : Buckles :Test buckles to make sure the coupling is secure. Webbing : look for frayed , cracked , cut , burned or damaged webbing and loose or broken stitching D-rings : look for bent, cracked , nicked or gouged rings..

Scene 46 (32m 6s)

How to Put on a Safety Harness. Step 1 Hold harness by back O-ring. Shake harness to allow all straps to fall in place. step 3 Slip straps over shoulders so O-ring is located in middle of back between shoulder blades. step 5 Connect chest strap and position in midchest area. Tighten to keep shoulder straps Step 2 If chest, leg and/or waist straps are buckled, release straps and unbuckle at this time Step 4 Pull leg strap between legs and connect to opposite end. Repeat with second leg strap. If belted harness, connect waist strap after leg straps step 6 After all straps have been buckled, tighten all buckles so that hamess fits snug but allows full range of movement. Pass excess strap through loop keepers. •e.

Scene 47 (32m 38s)

Anchorage and Lifelines. Examples of anchor devices - eyebolt (left), roof anchorage (centre) and anchor sling..

Scene 48 (32m 56s)

Anchorage and Lifelines. 1. Lifelines are flexible or rigid lines connected at least to one end to a reliable anchor to provide a link between the anchor and the user of a personal fall prevention/ arrest system. 2. Lifelines should meet the following characteristics: Safe rating high enough to withstand forces generated in the event of a fall; and Installed in a proper manner such that they do not interfere with any other items of equipment or clothing, or create any tripping hazards..

Scene 49 (33m 20s)

Anchorage and Lifelines. A self-retracting lifeline (SRL) involves a spring-loaded reel to ensure the shortest possible length of lifeline between the user and the reel. Where SRLs are used, it is important to note that unless tested and permitted by manufacturer: SRLs must not be used in the horizontal plane; SRLs must not be attached to a horizontal lifeline; A lanyard (with or without energy absorber) must not be attached between the SRL and the full body harness as this may increase the fall distance; and Attachment of more than one user to each SRL must not be allowed as overloading may occur..

Scene 50 (33m 47s)

100% TIE-OFF. Sankyu Singapore. 5BGR(1). DANGER FALL PROTECTION REQUIRED 100% TIE OFF.